Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

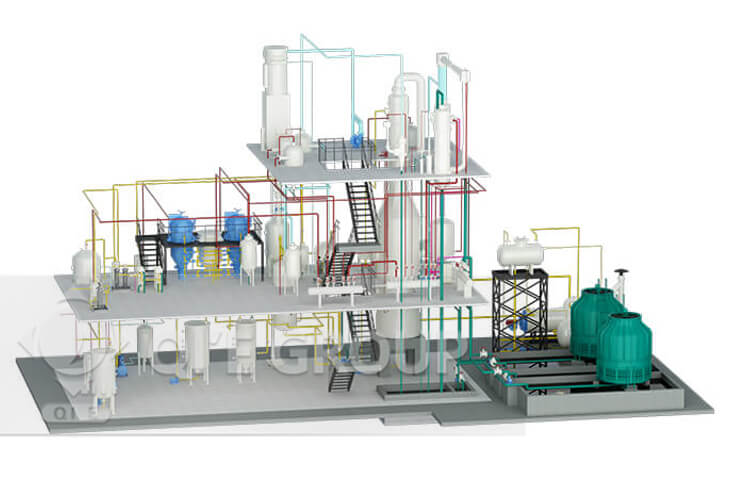

Palm oil fractionation is an important process of palm oil refining plant. This new type of palm oil fractionation equipment includes a new type of crystallization tank, a diaphragm filter and advanced automatic control system. It uses a scientific cooling and crystallization process to improve the yield of liquid palm oil.

Brand

QIE

Raw Material

Refined palm oil before fractionation

Capacity

Minimum 1TPD

1-1000TPD

Customized Palm Oil Fractionation Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

The oil degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Deacidification Process

Oil Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil.

Bleaching Process

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization Process

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester. Production Capacity:50-1000TPD

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

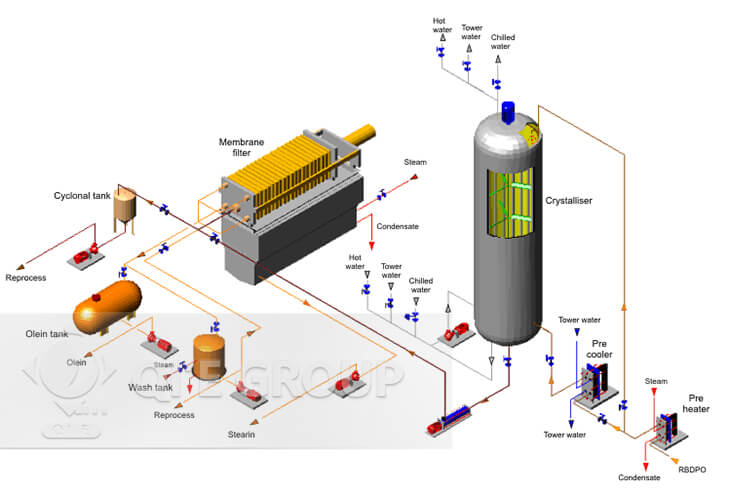

Learn MoreCooling/Crystallization: Palm oil is slowly cooled under controlled conditions to encourage the formation of solid stearin crystals while keeping olein liquid.

Filtration/Separation: The mixture of crystals and liquid is passed through filters (e.g., filter presses or centrifuges) to separate the solid stearin from the liquid olein.

Post-Treatment: The separated fractions may undergo further processing, such as reheating to remove residual moisture or refining to improve stability and quality.

Each stage is tightly controlled to ensure precise fractionation and consistent product quality.

Cooling Rate: Slow, uniform cooling promotes larger, more easily separable crystals; rapid cooling can cause small, irregular crystals that hinder filtration.

Oil Composition: The initial fatty acid profile of the palm oil (e.g., ratio of saturated to unsaturated fats) affects crystal formation.

Equipment Design: High-quality filters, temperature-controlled cooling systems, and efficient mixing mechanisms reduce processing time and improve separation.

Operational Parameters: Maintaining optimal temperatures (typically 20–25°C for crystallization) and pressure during filtration prevents fraction re-mixing.

Palm oil fractionation is a physical process. It relies on differences in the melting points of the oil’s components (triglycerides) rather than chemical reactions. No additives or chemicals are used to split the oil—separation occurs purely through controlled cooling and mechanical filtration. This makes the process environmentally friendly and preserves the natural properties of the fractions.

Cooling Tanks/ crystallizers: Insulated vessels with agitators to control cooling rates and crystal formation.

Filtration Systems: Filter presses, membrane filters, or centrifuges to separate stearin crystals from olein.

Heating/Cooling Units: Chillers and heaters to regulate temperatures during crystallization and post-separation handling.

Storage Tanks: Separate tanks for raw palm oil, intermediate mixtures, and final fractions (olein, stearin).

Control Panels: To monitor and adjust parameters like temperature, cooling rate, and filtration pressure for consistent results.

Fractionation does not alter the basic nutritional components (e.g., fatty acids, vitamins) of the fractions but redistributes them. Olein is richer in unsaturated fatty acids (e.g., oleic acid) and remains liquid, while stearin is higher in saturated fatty acids (e.g., palmitic acid) and solidifies. Both fractions retain natural antioxidants like carotenoids (if derived from crude palm oil) unless further refined. Nutritional labeling for each fraction reflects their unique fatty acid profiles.

Yes, fractionation plants can process both crude and refined palm oil, but pre-treatment may be required. Crude palm oil often contains impurities (e.g., moisture, free fatty acids) that can interfere with crystallization, so it is usually degummed or filtered first. Refined palm oil, having already undergone purification, fractionates more efficiently and produces higher-quality fractions with longer shelf lives. Some plants are designed to handle both feedstocks with adjustable processing steps.

Plant capacity ranges from small-scale (5–50 tons per day) to large industrial facilities (500+ tons per day). Scale is determined by:

Market Demand: Larger plants serve regional or global markets, while small-scale units cater to local needs.

Investment Budget: Higher capacity requires more equipment, larger infrastructure, and greater initial investment.

Feedstock Availability: Proximity to palm oil mills ensures a steady supply, making larger plants feasible in major palm oil-producing regions (e.g., Southeast Asia, West Africa).

Flexible designs allow some plants to adjust capacity by adding modular equipment, adapting to fluctuating demand.