Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

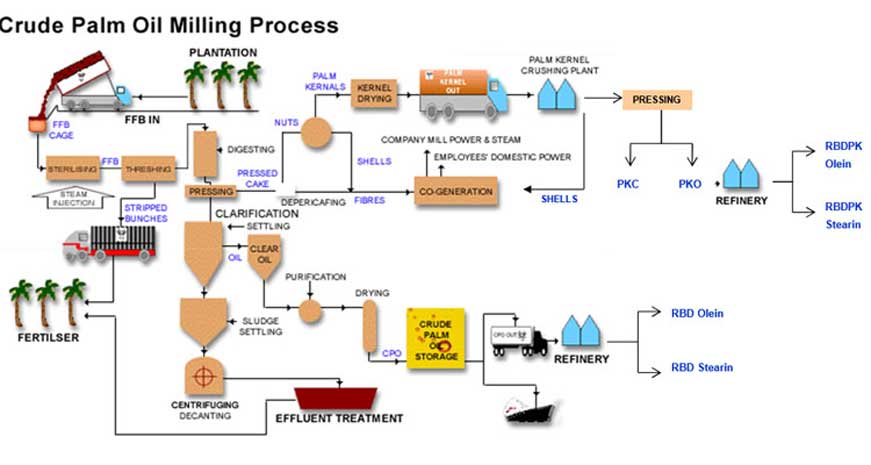

QIE Machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of palm oil production business. Main Machinery for Making Palm Oil: Steriliser, digester, stripper machine, screw press, nut/fiber separator and so on. The manufacture of crude palm oil involves a series of processes starting with harvesting fresh fruit bunches from the plantations and ending with crude palm oil storage. Through sterilizing, threshing, mashing and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press). Each station of palm oil mill uses different methods and machines. After purifying and refining, the refined palm oil can be exported as a popular kind of healthy and edible oil.

Brand

QIE

Raw Material

Palm Fruit,Palm Kernel

Capacity

1-120TPH

1-120TPH

Customized Palm Oil Mill Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

The oil degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Deacidification Process

Oil Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil.

Bleaching Process

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization Process

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester. Production Capacity:50-1000TPD

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

Learn MoreWorker safety is a top priority, with mills implementing strict protocols and equipment. All personnel receive training on handling heavy machinery, chemical use (for cleaning agents), and emergency procedures. Guards and safety barriers are installed around rotating equipment like threshers and presses to prevent accidents. Respiratory protection is mandatory in areas with dust from kernel processing, and heat-resistant clothing is provided for workers near sterilizers and boilers. Regular safety audits check for compliance, and first-aid stations with trained staff are strategically placed throughout the facility. Mills also enforce strict lockout-tagout procedures when maintaining machinery to avoid accidental startups.

Palm oil mills are often economic hubs in rural areas, providing direct employment to hundreds of workers—from machine operators and engineers to administrative staff. They also create indirect jobs in transportation (FFB delivery, CPO distribution), maintenance, and supply chain services. Many mills invest in community development, funding schools, healthcare clinics, and clean water projects. By purchasing FFBs from smallholder farmers, mills provide a stable income source, supporting agricultural livelihoods. Some mills also offer training programs for farmers on sustainable FFB cultivation, improving crop quality and yields for both parties.

FFB supply varies seasonally, with peak harvests in wet seasons and reduced yields in dry periods. Mills manage this by maintaining storage facilities for FFBs, though storage is limited to 24–48 hours to prevent spoilage. They also collaborate with multiple plantations and smallholders to diversify supply sources, reducing reliance on a single grower. During low-supply periods, mills may operate at reduced capacity or schedule maintenance shutdowns to align with lower input volumes. Some larger mills enter into long-term contracts with farmers, guaranteeing purchase prices to encourage consistent production, while others invest in irrigation systems for nearby plantations to stabilize off-season yields.

While both oils come from oil palm, their processing paths differ. CPO is extracted from the fleshy mesocarp of the fruit: after sterilization and threshing, the fruit is digested and pressed to release oil, which is then clarified. PKO, on the other hand, comes from the hard kernel inside the fruit. After pressing for CPO, the remaining fruitlets (with kernels) are dried to reduce moisture, then cracked to separate kernels from shells. The kernels are roasted to loosen oil, pressed or solvent-extracted to produce PKO, and the resulting cake is processed into animal feed. CPO is high in saturated fats and used in food products, while PKO is more similar to coconut oil, used in cosmetics and detergents.

Palm oil mills are significant contributors to renewable energy through biomass utilization. By-products like palm press fiber (PPF), empty fruit bunches (EFBs), and palm kernel shells (PKS) are burned in boilers to generate steam, which powers turbines for electricity. This "cogeneration" process meets the mill’s energy needs, with excess power often sold to local grids. Additionally, palm oil mill effluent (POME) undergoes anaerobic digestion to produce biogas—a mixture of methane and carbon dioxide—which is used for heating or electricity generation. A typical large mill can generate 1–3 megawatts of electricity from biomass, reducing its carbon footprint and reliance on fossil fuels.

Small-scale mills often struggle with lower efficiency due to outdated equipment, limiting oil extraction rates. They may lack the capital to invest in advanced technologies or waste treatment systems, leading to higher environmental impacts. Access to FFBs can be inconsistent, as smallholders may sell to larger mills offering better prices. Compliance with sustainability certifications is also harder for small mills, as the costs of audits and traceability systems are proportionally higher. Additionally, small mills may have limited access to markets for by-products like PKC, reducing revenue streams. However, they often have stronger ties to local communities and can adapt more quickly to local supply fluctuations.

FFB quality directly impacts oil yield and CPO quality. Overripe or underripe fruits have lower oil content—optimal ripeness (75–85% red/orange color) ensures maximum extraction. Damaged or moldy FFBs (from delayed harvesting or poor storage) increase free fatty acid (FFA) levels in CPO, reducing its value and shelf life. Contaminants like soil, stones, or twigs in FFBs can damage machinery and introduce impurities into the oil, requiring additional cleaning steps. Mills often reject low-quality FFBs or charge lower prices to encourage farmers to deliver only ripe, undamaged bunches. Proper handling of FFBs—from harvest to delivery—can increase mill efficiency by up to 15% and improve CPO marketability.