Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

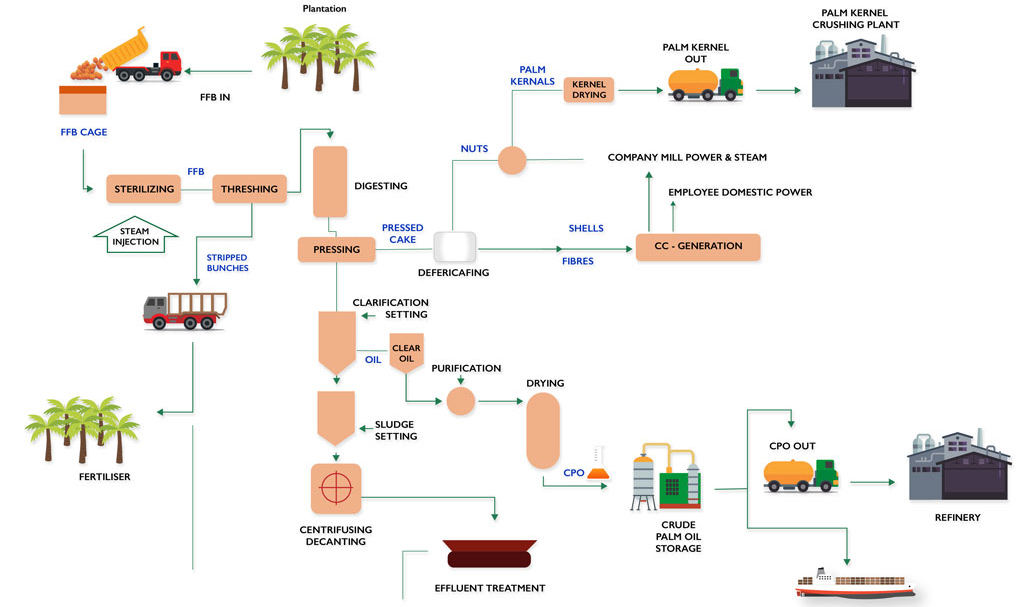

QIE Machinery can provide turnkey projects for large, medium and small palm oil production lines with a production capacity of 1~120tph. Let's take 10-120tph as an example to describe the palm oil production process.

We also can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A to Z for you.

Brand

QIE

Raw Material

Palm Fruit,Palm Kernel

Capacity

Minimum 1TPH

1-120TPH

Customized Palm Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

The oil degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Deacidification Process

Oil Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil.

Bleaching Process

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization Process

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester. Production Capacity:50-1000TPD

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

Learn MoreThe production line typically includes 7 core stages:

Reception & Cleaning: FFBs are unloaded, weighed, and cleaned to remove dirt, stones, and loose leaves.

Sterilization: FFBs are steamed at 120–140°C to stop enzymatic activity, loosen fruits from bunches, and soften mesocarps.

Threshing: Sterilized FFBs are mechanically beaten to separate individual fruits from bunches.

Digestion & Pressing: Fruits are crushed (digested) to break cell walls, then pressed to extract a mixture of crude palm oil, water, and solid impurities (pulp).

Clarification: The pressed mixture is heated and centrifuged to separate oil from water and solids, yielding crude palm oil (CPO).

Kernel Recovery: Solids from pressing are screened to collect palm kernels, which undergo separate processing (cracking, drying, pressing) to produce palm kernel oil (PKO).

Refining (Optional): CPO can be further refined (degumming, neutralization, bleaching, deodorization) to produce refined, bleached, and deodorized (RBD) palm oil for food use.

Palm oil production lines vary widely in capacity, from small-scale (50–500 kg of FFBs per hour) to large industrial plants (5–60 tons of FFBs per hour). Small lines are suitable for rural cooperatives, while large lines supply commercial markets. Capacity is determined by equipment size (e.g., sterilizers, presses, centrifuges) and can be scaled by adding parallel processing units. A 10-ton-per-hour FFB line, for example, can produce approximately 2–2.5 tons of CPO daily (assuming 20% oil extraction rate from FFBs).

Modern production lines achieve oil extraction rates (OER) of 18–22% for CPO from FFBs, meaning 1 ton of FFBs yields 180–220 kg of CPO. Efficiency depends on FFB quality (ripeness, freshness), sterilization time/temperature, and pressing equipment. Over-ripe or stale FFBs reduce OER due to FFA formation. Kernel recovery typically extracts 4–6% of PKO from FFBs (e.g., 40–60 kg of PKO per ton of FFBs). Advanced pressing technologies (e.g., screw presses) and proper maintenance can maximize extraction efficiency.

A basic line (for CPO production) requires:

Reception equipment (conveyors, cleaners, weighbridges).

Sterilizers (vertical or horizontal steam chambers).

Threshers (rotary drum or hammer mills).

Digester (steam-heated crusher) and screw press.

Clarification tanks (with heating coils) and centrifuges (decanters).

Storage tanks for crude palm oil.

For kernel processing, additional equipment includes kernel separators, dryers, cracker-separators, and kernel oil presses. Larger lines may add automation (e.g., PLC control systems) for monitoring and adjusting parameters like temperature and pressure.

Quality control measures include:

Strict FFB handling: Rapid processing post-harvest to limit FFA levels (target: <5% FFA in CPO).

Sterilization precision: Controlling steam pressure and time to avoid over- or under-sterilization.

Efficient clarification: Centrifugation to remove >95% of solids and moisture from pressed oil.

Testing: In-line or lab tests for FFA, moisture, impurity content, and color (e.g., using a Lovibond colorimeter).

Hygiene: Regular cleaning of equipment to prevent microbial contamination and off-flavors.

Refined oil lines add steps like degumming (removing phospholipids) and deodorization (stripping volatile compounds) to meet food-grade standards (e.g., <0.1% FFA for RBD palm oil).

Energy use depends on capacity: A 10-ton/hour FFB line consumes ~1.5–2.5 MWh of energy per ton of CPO, primarily from steam generation (for sterilization and digestion) and electric motors (conveyors, presses). Many plants use biomass (e.g., palm empty fruit bunches, fiber) as fuel for boilers, reducing reliance on fossil fuels.

Water consumption averages 3–5 cubic meters per ton of FFBs, used for cleaning, steam, and cooling. Modern lines recycle 50–70% of process water (e.g., from clarification) after treatment, minimizing waste. Wastewater (known as palm oil mill effluent, POME) is often treated in biogas plants to generate energy, making the process more sustainable.

Common challenges include:

FFB Supply & Quality: Ensuring a steady supply of ripe FFBs, especially in seasonal growing regions.

Maintenance: Screw presses and centrifuges require regular upkeep to prevent wear and maintain extraction efficiency.

Regulatory Compliance: Meeting environmental standards for wastewater discharge and emissions (e.g., EU regulations on POME treatment).

Cost Fluctuations: Volatility in FFB prices, energy costs, and global palm oil demand.

Labor: Skilled workers are needed to operate and monitor equipment, particularly in semi-automated lines.

Refinery plants transform crude palm oil (CPO) into edible oil through:

Degumming: Removal of phospholipids using phosphoric acid at 70-85°C

Bleaching: Adsorption of pigments/oxidation products with activated clay (0.5-2% dosage) at 100-110°C under vacuum

Deodorization: Steam distillation at 240-260°C under 2-6 mbar vacuum to remove free fatty acids (FFA) and odor compounds

Fractionation: Winterization at controlled temperatures (20-25°C) to separate olein (liquid) from stearin (solid)

Key machinery includes:

Degumming tanks with high-speed agitators

Bleaching vessels with vacuum systems (<50 mbar)

Deodorizers (semi-continuous or continuous) with fatty acid condensers

Heat recovery systems reducing steam consumption by 30-40%

Plate/frame filters for spent clay removal